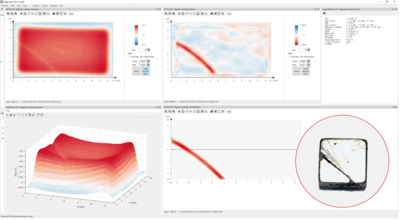

Magcam technology pushes the boundaries of magnetic field visualization with a magnetic field camera that measures the entire magnetic field in three dimensions (Bx, By, Bz), including the in-plane field direction (azimuth angle) and the out-of-plane field direction.

Understanding the magnetic field details is key for engineers to improve their magnetic assembly designs. Magcam's solution makes it possible to have insights into the poles’ magnetic intensity by identifying pole peaks, detecting zero-crossing, pinpointing inhomogeneities, etc. In high-performance applications, it is necessary, for instance, to have uniform pole height and symmetric North-South poles.