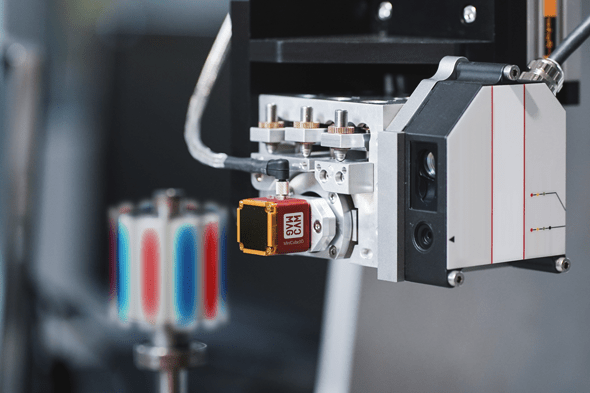

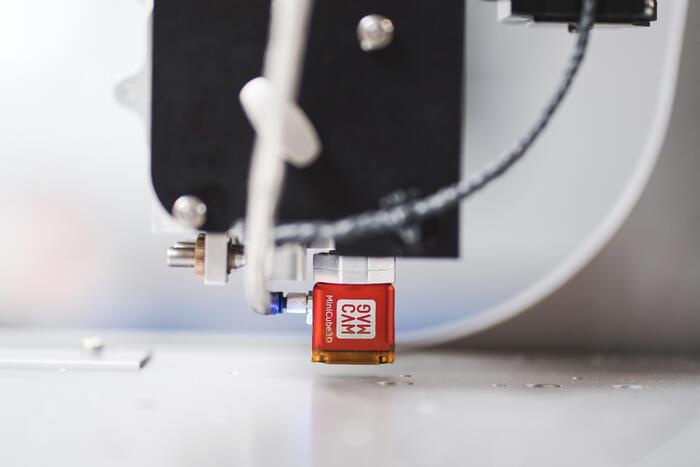

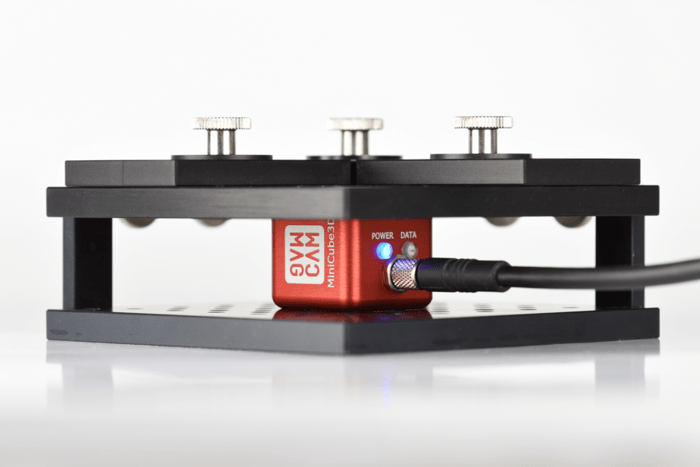

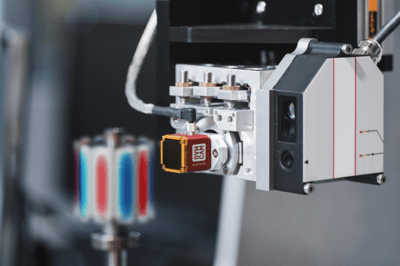

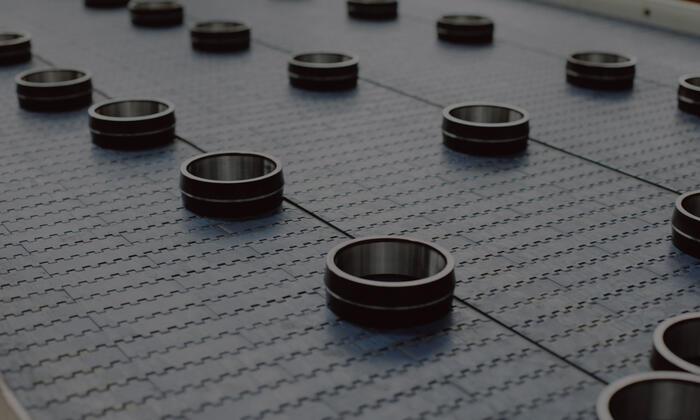

Magnets come in many shapes, types, and sizes in various applications, such as rotor magnets, linear encoder strip magnets, rotary encoder magnets, and sensor magnets. Especially in high-end applications where tight tolerances may be required. This in turn has led to the need for advanced magnetic field measurement systems. All it takes is choosing the right measurement solutions that break the barriers and can make the magnetic field visible and more accessible.