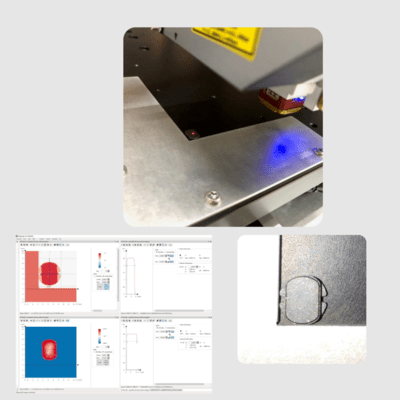

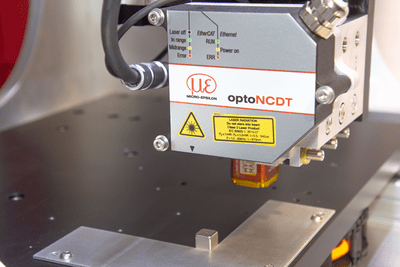

The first purpose of the Laser Distance Sensor is to measure the height test and position the MiniCube magnetic field camera at the correct distance above the sample during a magnetic measurement.

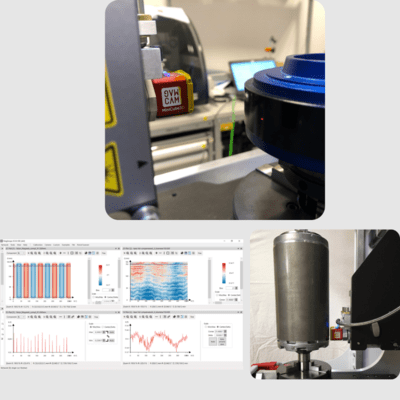

The laser is mounted on the Z-axis and moves together with the MiniCube magnetic field camera of the portal scanner or rotor inspector installation.

With one push on the start button, the different rotor inspection setups of Magcam can laser scan the surface of your rotor. The correlation between the magnetic field and non-perfect surfaces or unique geometries can thus be analyzed.