The Belgian Innoptus Solar Team, having previously won the title at the World Solar Challenge, has once again crowned themselves to World Champions. This time, they brought with them their latest marvel, the 'Infinite' race car, featuring a unique self-made axial-flux motor with advanced Halbach arrays in its dual rotor. When it came to ensuring the highest magnetic quality standards for this motor, Magcam became their go-to partner.

Breadcrumb

Winning the World Solar Challenge Champion title: Optimizing the Halbach array axial-flux motor of the Belgian Innoptus Solar Team

Powered by a Halbach axial-flux motor

Individual Magnet Scans

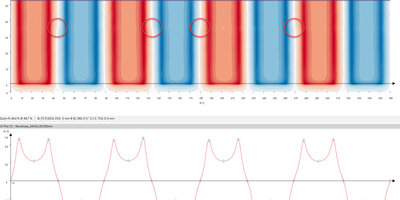

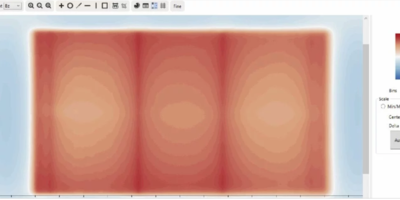

Prior to the assembly of the rotor, Magcam started out by measuring high resolution magnetic field distributions of the complete batch of individual magnets using its sophisticated magnetic field camera Combi Scanner. The measurements involved stepping Magcam’s MiniCube3D magnetic field camera over the magnet surface in a few steps at high speed and subsequently stitching the individual frames together. The integrated on-chip 2D array of over 16000 Hall effect sensors allowed for short cycle times.

From the subsequent analysis of the measured magnetic field distribution data emerged an array of quality parameters for each magnet, including magnet strength, magnetization angle error, and localized magnetic homogeneity maps, allowing in-depth quality assessments, unparalleled by any other magnetic inspection technique.

Magnet sorting and selection

After pouring the results in histograms, the quality variation within the batch of magnets could be visualized and further analyzed.

Since a Halbach array consists of magnets with different magnetization orientations that are placed in a well defined order, the analysis was performed for each type of magnets separately.

The goal of this analysis was to select only magnets with tight quality tolerances and to reject non-conforming magnets, thus preventing bad magnets from getting into the rotors and consequently deteriorating its performance.

A first pre-selection of magnets was done by rejecting all magnets that exhibited a too large magnetization vector angle deviation. Next, magnets that exhibited large inhomogeneities within their internal magnetization distribution were also removed, a characteristic that can only be measured using the combination of magnetic field mapping and Magcam’s proprietary analysis algorithms. Within the remaining sets of magnets, there still existed some variation in internal magnetization strength, a metric that Magcam’s algorithms can also extract from the external magnetic field distribution. Since the goal was to create a high-performing and uniform motor, the extremities of the histogram were rejected from the selection.

Rotor Magnetic Field Scans and Analysis

With the remaining set of magnets, of which each magnet was accurately characterized, the clever motor designers of the Innoptus Solar Team optimized the magnet layout for their two rotors, distributing any remaining differences in the magnets throughout the rotors, to ensure a maximally uniform magnetic field distribution. Using ingenious techniques, the magnets were then assembled into the rotors. After assembly, Magcam’s Combi Scanner was once again in action to measure fast, high resolution magnetic field distribution maps of the rotors.

The magnetic measurements were preceded by a laser surface mapping using the scanner's integrated high accuracy laser sensor. These measurements reveal the mechanical (axial) height distribution of the magnets along the rotor periphery, which can have effects on the resulting magnetic field distribution.

The resulting magnetic field maps were analyzed using Magcam’s sophisticated algorithms in order to unveil magnetic rotor parameters including pole angle consistency, pole strength uniformity, field gradient variations and north/south symmetry. These parameters are known to correlate with functional motor parameters such as cogging torque, torque ripple and efficiency.

"Thanks to the magnet preselection and rotor optimization by Magcam, we were able to maximize the efficiency of our motor, giving us a clear competitive edge in the race," says Stan Kelchtermans, who designed and constructed the innovative motor.

Becoming World Champions

All this work was not without result. After securing a second starting place during the qualifications in Darwin, the Innoptus Solar Team with their innovative vehicle 'Infinite' quickly took the lead after only one hour of racing on the first day and has kept its place since, going at unprecedented speeds in the 3022km long race through Australia's outback. After a perfectly executed race over five days, they finished first in Adelaide with a 20 minute lead over the runner-up team from the Netherlands and thus became world champions for the second time in a row.

Magcam is extremely proud to have made a contribution to this extraordinary result.

Start improving your electric motor performance too

As demonstrated in this case study, achieving remarkable enhancements in electric motor performance is within reach when equipped with the right tools and partnered with the right expertise. Magcam stands as your trusted ally, offering state-of-the-art technology to facilitate unprecedented advancements in motor performance. Don’t settle for less; reach out to us today to explore how we can support you to craft top-tier electric motors that set new industry standards.